Modern printing uses direct-to-film (DTF) printing and UV DTF printing. They are revolutionizing the textile and garment industry.

Both have unique advantages and capabilities. But, businesses must understand their differences. They aim to optimize their production processes.

This article delves into DTF printing and UV DTF printing. It compares their features, benefits, and suitability for business needs.

Understanding DTF Printing

DTF Printing is a digital method. It’s widely used in textiles. The process involves printing designs onto a heat-sensitive film with an inkjet printer. Then, you transfer them onto the fabric using a heat press machine. This process allows for vibrant, high-res designs. It works on fabrics like cotton and polyester blends.

DTF printing offers cheap solutions for complex designs. It is gaining popularity for its speed compared to traditional methods. These methods include screen printing and direct-to-garment printing.

Good points of DTF Printing:

1. DTF printing offers vivid colours and exceptional accuracy. It allows businesses to reproduce intricate designs with stunning clarity.

2. DTF printing supports many fabrics, like cotton, polyester, and blends. It’s good for many garment types and materials.

3. The ink used in DTF printing bonds strongly with the fabric. Its Prints are durable and resistant to fading, cracking, and peeling.

Limitations of DTF Printing:

1. DTF printing requires careful film preparation, including coating and drying. These steps can make the process take longer than other methods.

2. This requires a big upfront investment. You have to make an initial investment. You will have to buy the equipment for DTF printing, including printers and heat presses.

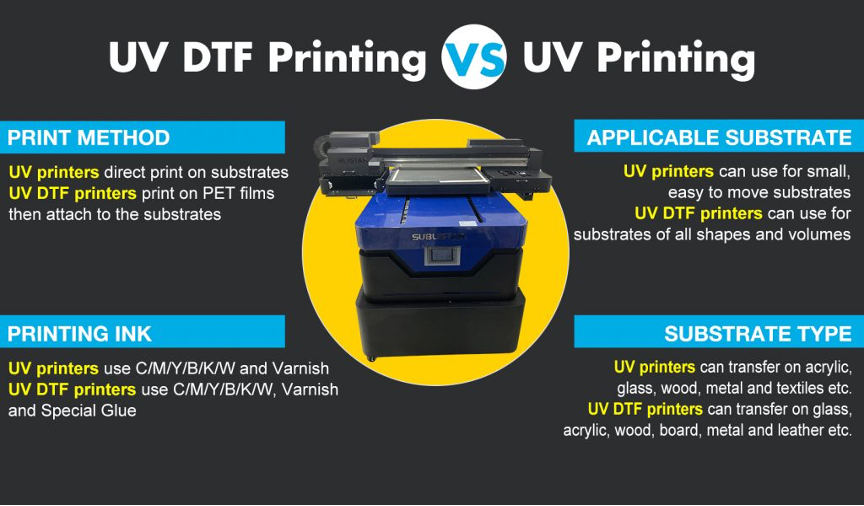

Exploring UV DTF Printing

UV DTF printing combines film printing with UV-curable ink. It is more efficient and versatile. This method exposes the printed design on the DTF film to UV light. The light cures the ink instantly, removing the need for a heat press transfer.

Good points of UV DTF Printing:

1. UV DTF printing speeds up production. It cuts the heat press step, allowing for faster turnaround and more output.

2. UV DTF printing is energy efficient. It does not need heat to cure ink, unlike traditional DTF printing. This cuts energy use and costs.

3. UV-curable inks stick to more materials. These include rigid ones like wood, metal, and acrylic. This expands the range of materials they can bend to. It opens new options for product customization.

Limitations of UV DTF Printing:

1. UV-curable inks offer durability and fast curing. However, they may need to be more flexible than traditional DTF inks. This flexibility could change how the printed garment feels.

2. UV DTF printers and UV curing systems usually cost more. They cost more than their conventional counterparts. This higher price tag may be a barrier to entry for some businesses.

Visit DTFLINKO for a more comprehensive insight into both types of Printers.

The Exact Solution for Your Business

When choosing between DTF and UV DTF printing, many factors matter. These include production needs, budget limits, and print quality goals.

To help businesses make an informed choice, we have outlined some crucial aspects:

1. Production volume

Businesses with high-volume printing requirements and tight deadlines can benefit from UV DTF printing. It is faster and more efficient. This makes it ideal for mass production and on-demand printing.

2. Print Quality

Both methods produce good-looking colours that last a long time. However, DTF printing may offer slightly better flexibility and texture. This is especially true for soft textiles like cotton garments. Businesses prioritizing print feel and comfort may lean towards traditional DTF printing.

3. Material Diversity

Your business involves printing on many substrates. These include textiles, as well as promotional items or signage. UV DTF printing is flexible. It makes it easy to handle diverse materials, expanding what you can offer and who you can sell to.

4. Budget

You must assess the cost to start and run each printing method. This is crucial for budget-conscious businesses. UV DTF printing is efficient and uses less energy. However, its upfront costs may be higher than traditional DTF printing.

What You Didn’t Know About Writing(Opens in a new browser tab)

Final Thoughts

Textile printing is changing fast. You have to pick between two methods: DTF and UV DTF printing. It’s a big decision, so you must consider your goals, how much you produce, and your budget.

DTF printing is good for colours and fabrics. But, UV DTF printing is faster and works with more materials.

Both methods offer new chances for growth and creativity. The right choice depends on what’s most important to your business. This could be Quality, speed, or the materials you use.

Thanks for reading this guide!